🚀 Become a Verified Author on Trending Hub24

✍️ Author Account Available @ $60 / Month | +91 7355993756

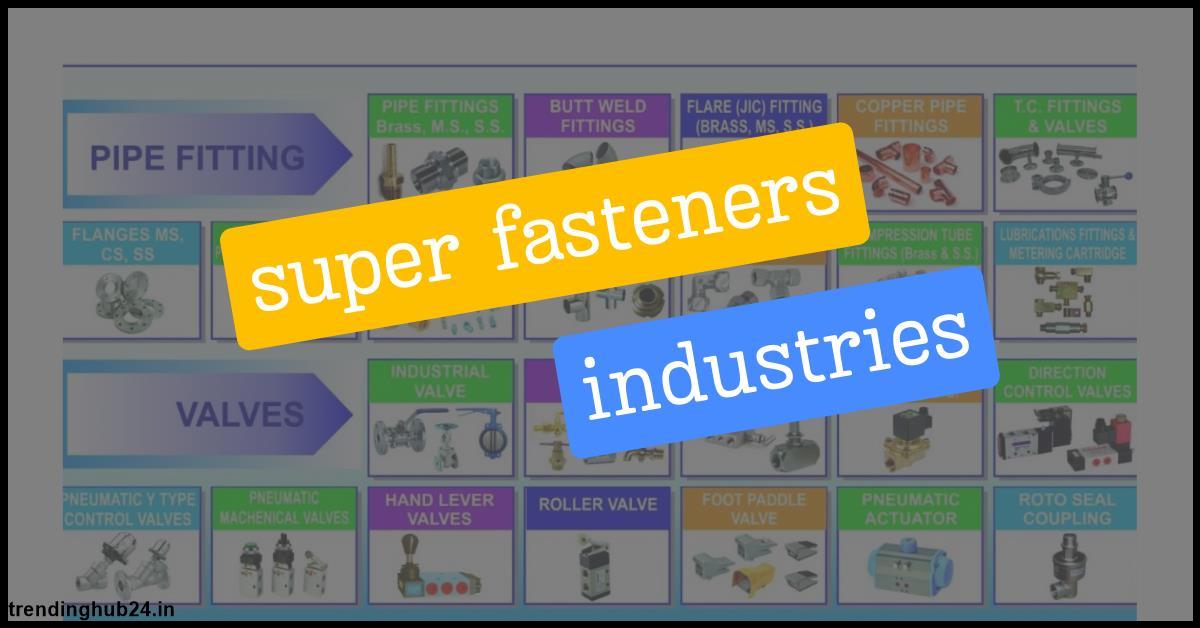

Role of Growing Super Fasteners Industries

Super Fasteners Industries Mumbai is a key contributor to the growth of the industrial and construction industries by offering high-quality fasteners.

Table of Contents

The role of Super Fasteners Industries in strengthening manufacturing and construction:

By offering premium fasteners, Super Fasteners Industries significantly contributes to the growth of the manufacturing and construction sectors. Ensuring structural integrity and safety is crucial in engineering and building projects.

Any structure's strength and efficacy of connections between its numerous components determine its stability and reliability. Fasteners have become quite important in this situation.

Fasteners are critical hardware components that securely connect distinct portions of a structure. They provide the necessary strength and stability. Learn the role of fasteners in enhancing the efficiency in manufacturing and construction:

Role of Super Fasteners Industries in Structural Integrity:

To keep buildings, bridges, and other structures structurally sound, industrial bolts and screws are essential. The support and reinforcement required to maintain structural elements together ensure stability and resistance to outside pressures like wind, seismic activity, and dynamic loads.

There would be serious safety issues for the general public and building occupants if there were no sturdy fasteners to support the structure.

What are the other roles of these fasteners in Construction?

Fasteners for Concrete:

You may or may not be aware of the reasons behind the necessity for concrete-specific nails and screws while working with concrete.

This is usually because fasteners made specifically for use with concrete include highly durable threads, corrosion-resistant coatings, or toughened coatings.

If you're working with concrete, you should use fasteners like these concrete pins because driving them will require additional strength to avoid breaking the fastening.

Compatibility of Materials:

Certain fasteners, compatible with the qualities of various building materials, including composite materials, steel, concrete, and wood, are needed.

Factors such as thermal expansion, galvanic corrosion, and differential movement between materials should be considered during the choosing procedure.

The Environmental Factors:

Many environmental factors, such as humidity, temperature fluctuations, and chemical exposure, are present throughout construction operations.

The right coatings or materials for fasteners should be selected to provide resistance to corrosion and other types of degradation under particular environmental conditions.

Inspections and quality control:

Ensuring the integrity of fasteners in construction requires quality control procedures, such as routine inspections.

Maintaining the structure's long-term stability requires proper torque, adherence to installation instructions, and inspections for symptoms of wear, corrosion, or loosening.

Role of fasteners in manufacturing:

Assembly and Installation:

Industrial fasteners are frequently used in manufacturing industries for assembly and installation procedures. They enable the safe and effective joining of parts, making the production of intricate machinery, equipment, and goods easier.

Industrial bolts and screws are crucial for streamlining production processes, whether they are used in furniture construction, factory machinery installation, or auto part assembly. They ensure consistency and quality of the product.

Compliance and Safety

To ensure the safety and compliance of manufacturing and construction operations, industrial bolts and screws are essential.

To comply with building regulations, industrial standards, and regulatory requirements for structural stability, fasteners must be installed and chosen correctly.

This ensures load-bearing capacity and addresses safety concerns. The integrity of equipment and structures is jeopardized when subpar or improper fasteners are used. This can result in expensive repairs, mishaps, and legal problems.

Cost-Effectiveness

Despite making up a comparatively tiny percentage of the total production and construction cost, industrial fasteners are extremely important. Early investments in high-quality fasteners and appropriate installation techniques can achieve long-term savings on expensive repairs, downtime, and safety events.

Furthermore, fasteners make it easier to use modular building and assembly methods. It lowers labor costs and construction schedules and eventually results in cost savings and better productivity.

Creative Thinking and Progress

With constant developments and advancements in materials, design, and manufacturing processes, the world of industrial bolts and screws is still changing today. Modern fasteners are designed to provide increased performance, efficiency, and sustainability to satisfy the evolving demands of the industrial and construction sectors.

These improvements, which range from eco-friendly coatings to self-locking mechanisms, make improved functionality, dependability, and environmental responsibility possible.

Selecting the Proper Fasteners

The proper fastener type must be used to ensure structural integrity and safety. The fastener's material, load-bearing capability, resistance to corrosion, and compatibility with the materials being joined are all important considerations.

High-quality goods that adhere to safety regulations and industry standards are guaranteed when using fasteners from reliable super fasteners industries in Mumbai Maharashtra.

Final words:

Super Fasteners Industries Mumbai is a key contributor to the growth of the industrial and construction industries by offering high-quality fasteners. Furthermore, choosing dependable, high-quality fasteners is critical to eliminate risks and ensure the security of employees and people.